Top 2022 Tools and Equipment in the Oil and Gas Industry

With a new year comes a new set of trends in any line of work, but this is especially the case in oil and gas industry. Oil and gas are in constant demand, so oilfield tools need to be able to evolve to meet that demand. Below we will take a look at the tools we predict will be especially popular in 2022 for their cutting-edge technology and ease-of-use.

Tool: Power Tongs

We predict that power tongs will continue to be an invaluable tool in the oil industry as they are continuously developed to improve efficiency and the safety of drill floor operations. These wrenches are well-known for their ability to apply torque and gripping drill string components which is something that will not be replicated in 2022 by any other tool.

Power tongs are generally categorized into four types: casing tongs, tubing tongs, drill pipe tongs and riser tongs. Each variation has its place in 2022’s tool line-up.

- Casing tongs come in a variety of sizes and are used to make or break casing tubulars. They’re essential is maintaining the opening of the well.

- As you might imagine from their name, tubing tongs are used to run tubulars. This allows oil and gas to actually be extracted from reservoirs.

- Drill pipe tongs screw together drill pipe and tubulars to form drill strings. Drill strings are then used for drilling into the ground.

- Riser tongs are used when working with the seafloor. They move materials from the blowout (located on the seafloor) to the drilling rig.

When you invest in any essential power tong variation you can be sure that it will continue to be used for years to come.

Tool: Elevators

If you need to raise and lower pipe into the drilling hole, you need a drill pipe elevator. The use of an elevator in the oil industry ensures that the project can be completed. Without an elevator, many jobs would go unfinished which is why it’s on our list for the top oil and gas tools in 2022.

For some additional context, the elevator attaches to the top of the pipe joints in the drill string. This allows your driller to manage the movement of the pipe. Many elevators are hinged, so they are operated by opening the latch with two handles on each side. If you’re working on a heavy-duty drilling project, you will need to add an elevator to your arsenal of tools.

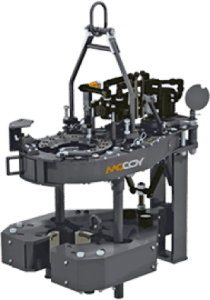

Tool: Top Drive Systems

A top drive system is used to apply clockwise torque to the drillstring to create a borehole. These mechanical systems are an alternative to the rotary table and kelly drive.

Top drive systems can be found on the drilling rig, below the traveling block, at the swivel’s place. They move up and down to evenly apply torque to the drillstring and can be used in a variety of rigs including truck-mounted rigs and offshore rigs.

Because top drives don’t require kelly drives, a master bushing and rotary table should instead be used for support. The lack of kelly drive makes a top drive system more scalable and is essential for 2022 drilling operations. With a top drive system you can drill 90 feet before making a connection whereas with kelly systems you only have 30 feet before making a connection.

The last benefit of a top drive system we will mention is they allow rotation and circulation while back reaming out of a hole; kelly drives do not have this capability and can’t rotate the drill stem.

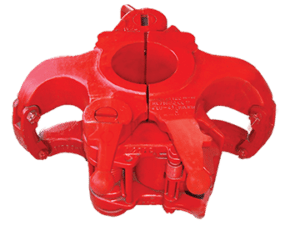

Tool: Rig Tongs

We can’t discuss the top tools of 2022 without touching on rig tongs. Rig tongs are self-locking wrenches that are used to breakout or makeup casing, tubing, or drill pipes. Examples of rig tongs are chisel tongs, casing tongs, power tongs, rotary tongs, and manual tongs.

Rig tongs are always used in pairs – one set is tied to the derrick with a cable or chain, while the other is pulled with mechanical catheads. The application of the rig tongs is dependent on torque necessary to breakout or makeup the casing or tubing.

There are three main types of rig tongs: straight tong tie drivers, angled tong tie drivers, and hammerless tong tie drivers. While all variations are used for die reslotting, they each have their own features for their specific applications.

Straight tong tie drivers are the simplest rig tong as they are straight, but they can also be the most dangerous as there is nothing to protect the operator from the hammer. As the name suggests, angled tong tie drivers have a grip that’s angled to create a perpendicular tong; they also have brass guards for the tips and handle. Finally, hammerless tong tie drivers don’t involve the use of a hammer, so they’re the safest, but they’re also the slowest for the same reason. The rig tong you choose should be specific to your jobsite.

Although there are a plethora of other tools vital to the oil and gas industry in 2022, power tongs and elevators are two of our favorite. If you’re ready to purchase the drilling rig equipment, contact us today! We’re happy to answer any questions you may have or help you complete your purchase.

.

.