The Benefits of Casing Running Tools

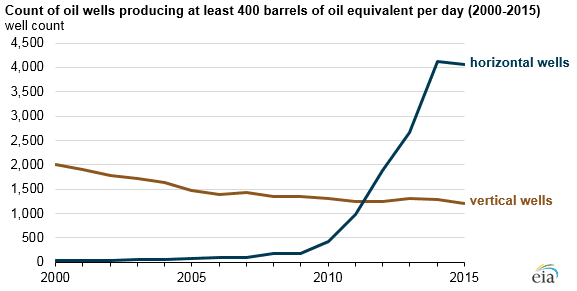

As you may be aware in 2015 nearly 77% of the most productive U.S. oil wells, those generating more than 400 barrels of oil per day, were horizontally drilled wells.

Source: US Energy Information Administration

Out on the field and dealing with both drilling and hydraulic fracturing has its challenges. However casing running tools (CRT) help make it much easier to ensure continued operations with significantly fewer workers.

CRT maximizes the torque of the top drive, so casing tongs, drilling bails, and stabbers aren’t necessary. Manual issues from the stabbing board operator are gone.

When CRTs are installed it includes the equivalent of spider elevator through drilling rig slips. Size of slips depend on the casing size transmitting the torque and the weight of casing strings. The CRT supports the single joint elevators as they lift to the well center. Once slips are on the joints, the top drive has enough energy.

No Manual Backup Tongs

With CRT you don’t necessarily need a manual backup tong. Not having to use tongs is likely preferable to most oil workers where most people argue over who is forced to use it when CRTs eliminate that undesirable task.

Additionally you’re producing much faster as there’s no down time for manual tongs and other equipment. With fewer people and manual tools on the field, human error and hazards diminish. Less time rigging and less equipment also lets you finish tasks faster.

Remote Operation

Control panel only requires one person and is simple to operate. With the Casing Drive System and slips, it’s much easier to avoid dropped or lost pipes. Effectively with casing running tools you get a smoother and more efficient casing along with less hazards and labor needed.

Learn more about Texas International Oilfield Tools.

.

.