A Guide to Safety Clamps

What are Safety Clamps?

Safety clamps are an important safety feature of any drill site! They are primarily used as a backup safety mechanism against drill pipe slippage for slips and other gripping devices. Safety clamps can also provide additional control in the case of component failure.

In this blog post we will focus on a detailed explanation of safety clamps and how they should be implemented on your drilling site for optimal performance. Let’s dive in!

Safety Clamp Implementation

Slips are created to taper and wedge tightly with the rotary bushings. They were designed this way so that the serrated teeth inside the slips will grip the pipe and stabilize and suspend the drill string in the rotary table. However, if the slips don’t have sufficient grip, the pipe could slip and cause major damage – so safety clamps were created.

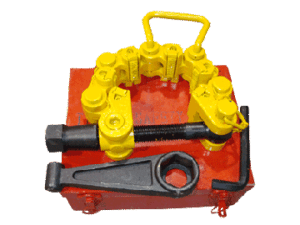

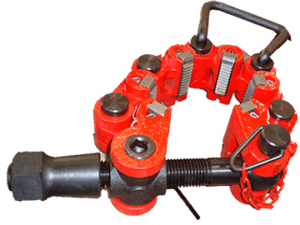

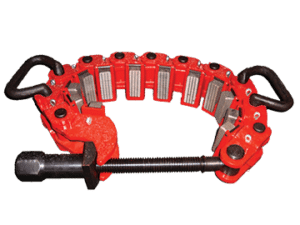

Safety clamps are used in conjunction with slips as an extra precaution against costly damaged and lost production time. Safety clamps are manufactured using individual, tapered links that are hinged for flexibility. Depending on the type of safety clamp, individual sections can be added or removed to accommodate different sized pipes, making them a flexible solution for a variety of drill sites.

Each link that composes the safety clamps is created with its own set of spring-loaded teeth to firmly grip the pipe. If the slip fails or the pipe begins to fall, the spring-loaded teeth absorb the impact and the safety clamps wedge tighter against the pipe. This ensures that there is no further slippage and keeps the pipe free from damage.

Types of Safety Clamps

There are three main types of safety clamps: Type C, Type T, Type MP.

The Type C safety clamp is available in multiple sizes (3.75” to 47’) and variations, including single screw and double screw designs.

Type T clamps on the other hand are designed to fit smaller pipes (ranging from 1.125” to 30.5”).

Type MP safety clamps are designed for pipes with a diameter range of 2.875” to 30.5” and offer significant flexibility. Unlike the other clamp types, each MP safety clamp comes standard with its own aluminum box.

All three safety clamp options are outfitted with handles or a lifting clevis to improve physical handling. No matter which safety clamp type you select, you can rest assured that they will add an extra layer of safety precautions without complicating your drilling operations.

Adding safety clamps to your drilling site is a no-brainer, and so is sourcing your clamps through Texas International Oilfield Tools. Give our experts a call today to place your safety clamps order!

.

.