How to Case a Well

Casing a well is also known as setting pipe because when you’re casing a well, you’re running a steel pipe into the well’s drilling hole. The small space in between the pipe and the raw well sides are filled with cement to steady and properly set the casing pipe into place.

Now that you understand the importance of casing, we will go into how to actually case your well below!

Casing a Well

Casing is created in sections (also known as joints) that are screwed together to form longer lengths of casing. This manufacturing ensures that they’re customizable for any drilling length.

Here’s a breakdown of how casing is screwed together:

- Each end of the casing sections has male threads

- Each joint connector (called collars or coupling) has female threads and is used to connect the two male joint ends

- Because the joint connectors are wider in diameter than the casing joints, the joints are become tightly sealed together

- To reinforce the seal a thread compound is added to the connection

When you run casing, you start on the rig floor, using casing elevators (which are stabbed into the previous casing string) on a traveling block to move the pieces of casing up and down through the drilling hole. While they’re hanging above the drilling floor, casing tongs screw the casing joints and the casing strings together. To properly place the casing, the first casing string and a guide shoe are used the direct the casing crew into the correct position.

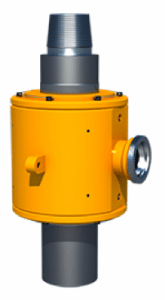

Casing has officially run into the well when the weight of the casing string is transferred to the casing hangers, located on the top of the well. At this point, a drill bit is inserted and drilling fluid is circulated to remove any leftover cuttings from the well. Once the leftover cuttings have been removed, cement is added to the narrow gaps in between the casing and the raw well walls to harden and set the casing in place.

Do you need to add casing to your well? We have all the casing and implementation tools you will need available! Just give us a call today.

.

.